PRODUCT

Rich engineering experience

ProductCenter

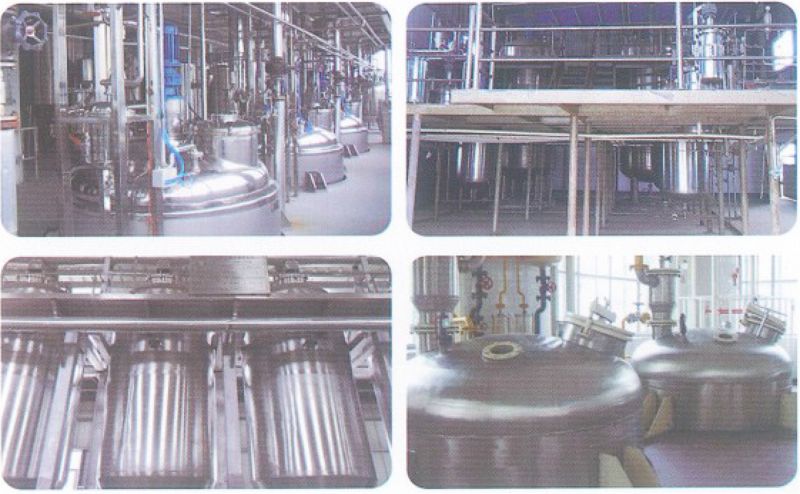

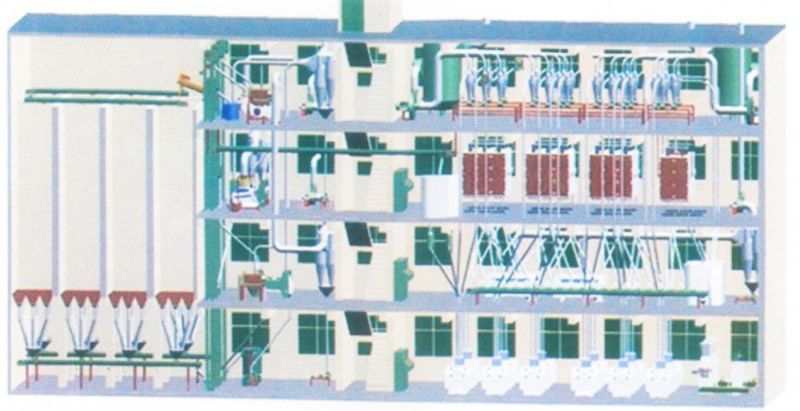

Oil production line

Creating products through innovation

CASES

Be diligent in every detail

TEL:+86-139-3999-7827

MESSAGE

ABOUT US

Creating products through innovation

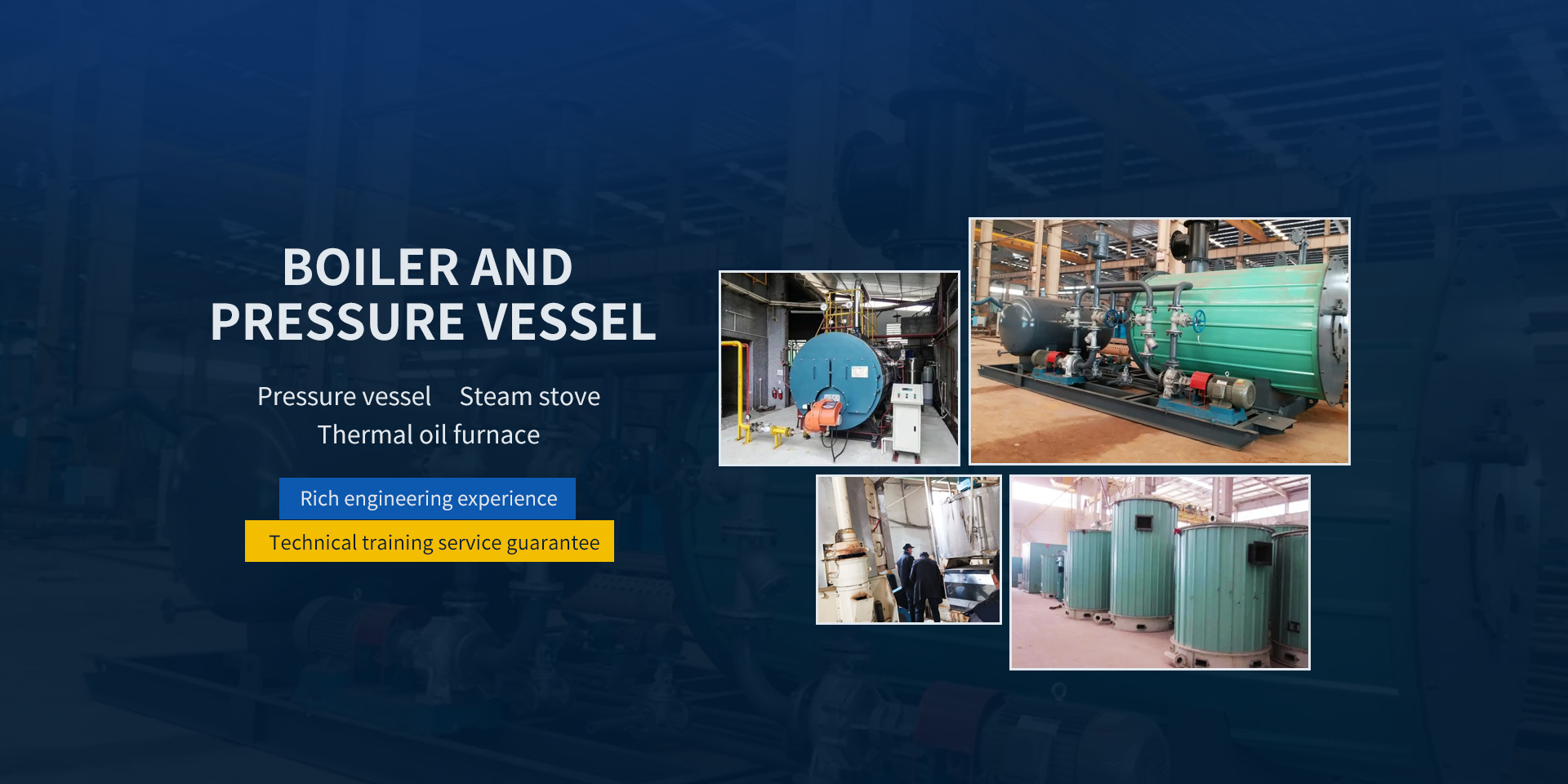

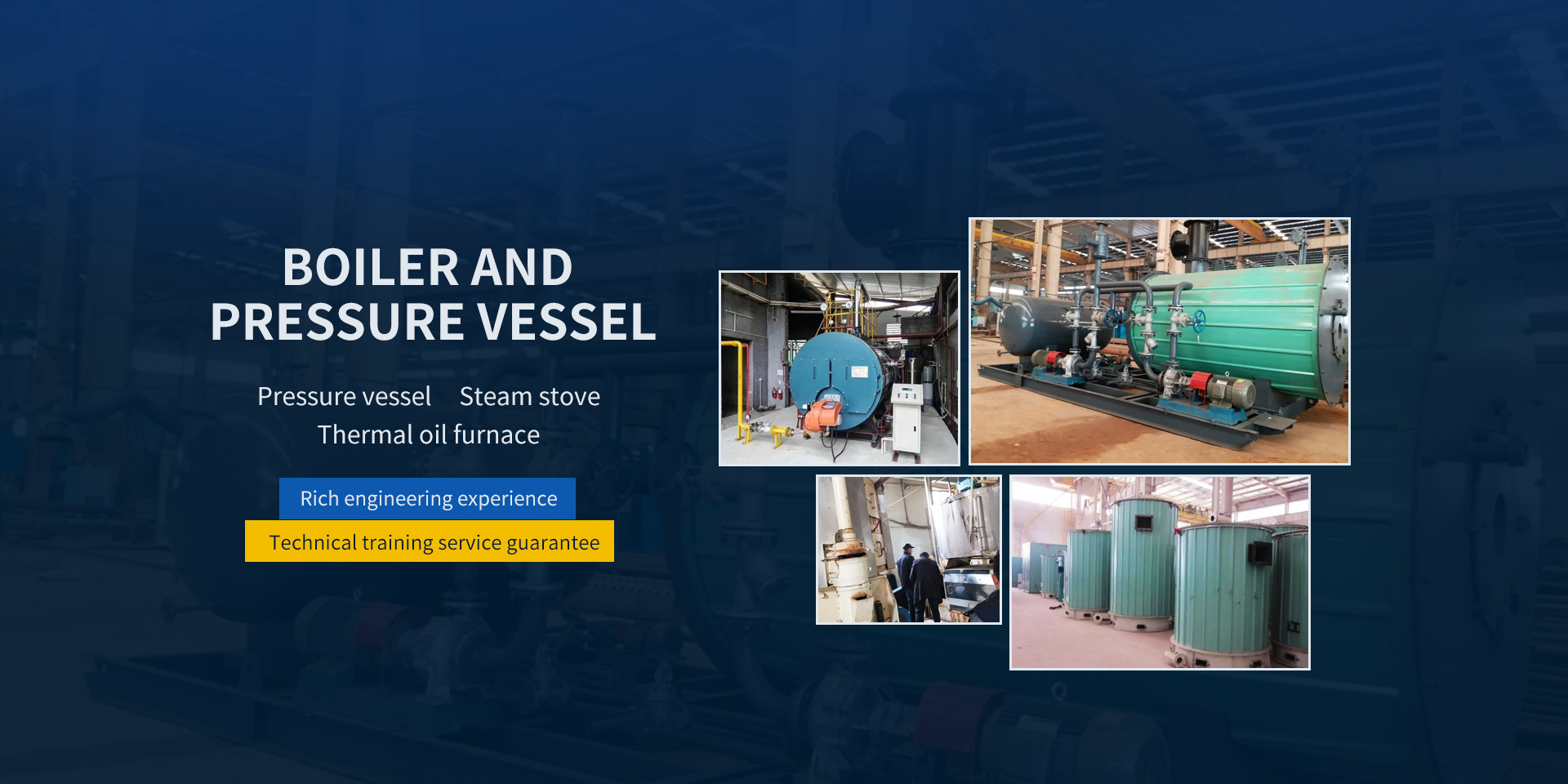

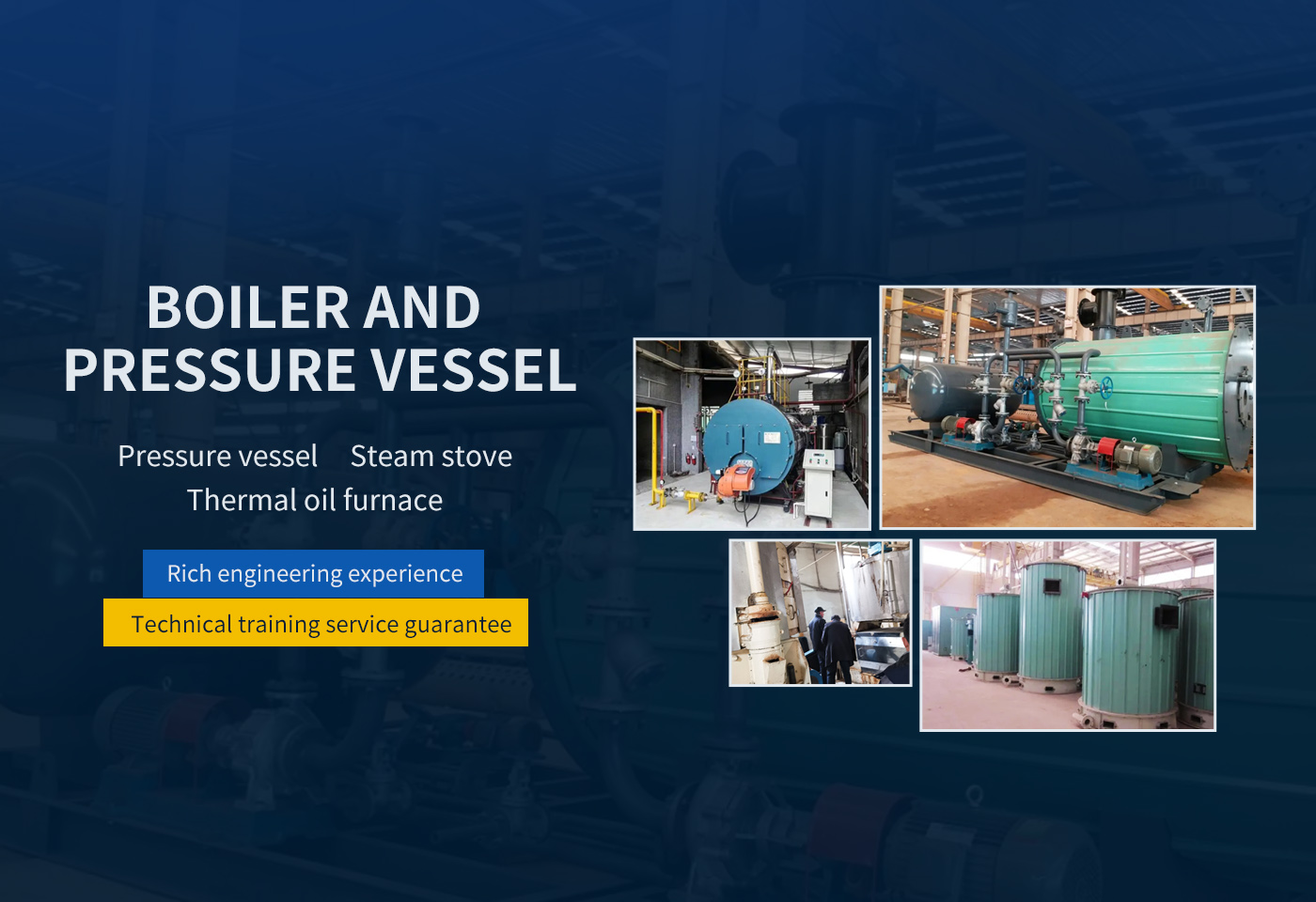

Henan Jianhuang Grain and Oil Machinery Co., Ltd. has been committed to the research and development and manufacturing of grain processing machinery and oil chemical equipment, as well as the design of various grain milling projects and the complete set of pre-treatment, oil extraction, leaching, and refining projects for all oil materials, as well as conveying equipment, lifting equipment, milling equipment, drying equipment, pressure vessel boilers and accessories, and packaging equipment. We have rich experience and theoretical foundation in manufacturing, installation, debugging, and technical training The product is best-selling in over 30 provinces and cities, and is exported to over 40 countries and regions such as Latin America, Southeast Asia, Africa, and Central Asia. And we sincerely cooperate with authoritative research institutions such as Beijing University of Science and Technology, Henan University of Technology, and Zhengzhou Grain Institute

NEWS

Targeting customer satisfaction

How to choose equipment suitable for oil refining?

2023-10-24

Choosing equipment suitable for oil refining requires considering multiple factors, such as production scale, process requirements, energy consumption, equipment operation and maintenance, etc. The following is a brief introduction to some commonly used equipment and considerations Oil refining equipmentFirstly, the production capacity of the equipment is one of the important factors in selecting the equipment.. Choosing appropriate equipment based on production scale can improve production efficiency and reduce costs. Common oil refining equipment includes small centrifuges, screw presses, and continuous frying equipment. Small centrifuges are suitable for small-scale production and can perform simple solid-liquid separation of crude oil; The screw press is suitable for small and medium-sized production and can perform preliminary physical crushing of crude oil; Continuous frying equipment is suitable for large-scale production and can perform complex physical and chemical treatments on crude oil Secondly, process requirements are one of the key factors in selecting equipment. Different process requirements require different equipment to meet. Common requirements for oil refining processes include deacidification, dewaxing, desliming, decolorization, deodorization, etc. Choosing suitable equipment can meet these requirements while maintaining the quality and nutritional composition of the oil Oil refining equipmentThirdly, energy consumption is one of the important factors to consider when selecting equipment.. The energy consumption of different equipment varies greatly, and choosing equipment with lower energy consumption can reduce production costs and improve environmental sustainability. For example, selecting equipment and technologies that can save energy and reduce consumption, such as heat exchangers, waste heat recovery systems, etc Fourthly, the operation and maintenance of equipment is one of the important considerations in selecting equipment. The difficulty of operating and maintaining equipment varies, and choosing equipment that is easy to operate and maintain can improve production efficiency and extend equipment life. In addition, the safety and reliability of equipment are also important factors in selecting equipment, and it is necessary to consider the safety measures and fault detection and protection system of the equipment It is also necessary to consider the price and supply channel of the equipment. Different equipment suppliers provide different equipment prices and after-sales services. Choosing a reliable supplier can ensure the quality of equipment and the reliability of after-sales service

Types, technical requirements, and brands of oil refining equipment

2023-10-24

Oil refining is an important step in producing high-quality oil, and selecting suitable equipment is the key to ensuring the smooth progress of the refining process. This article will introduce how to choose equipment suitable for oil refining, including equipment types, technical requirements, brand selection, and other aspects Oil refining equipmentFirstly, the type of equipment is the primary consideration for selecting equipment.. There are two common types of oil refining equipment: physical refining equipment and chemical refining equipment. Physical refining equipment mainly refines fats and oils through physical processes such as evaporation, distillation, deacidification, and dewaxing, suitable for vegetable and animal oils; Chemical refining equipment, on the other hand, refines fats and oils through chemical processes such as acidification, decolorization, and deodorization, making it suitable for fats and oils with higher acid values in vegetable oils. Choose different types of equipment based on specific needs Secondly, technical requirements are also an important factor in selecting equipment. When selecting physical refining equipment, technical indicators such as deacidification effect, evaporation efficiency, and dewaxing effect of the equipment should be considered. The deacidification effect is a key indicator for measuring the effectiveness of deacidification equipment, and equipment with high deacidification effect should be selected to ensure oil quality. The evaporation efficiency is related to production capacity and energy consumption, and equipment with higher evaporation efficiency should be selected to improve refining efficiency. The dewaxing effect is an important indicator for measuring the effectiveness of dewaxing equipment, and equipment that can effectively remove wax should be selected Oil refining equipmentFor chemical refining equipment, technical indicators such as acid value, decolorization degree, and deodorization effect should be considered.. Acid value is an important indicator to measure the effectiveness of acidification equipment, and equipment that can achieve lower acid value should be selected to improve oil quality. The decolorization degree is a key indicator to measure the effectiveness of decolorization equipment, and equipment that can achieve high decolorization degree should be selected to improve the color of oil. Deodorization effect is a key indicator for measuring the effectiveness of deodorization equipment, and equipment that can achieve good deodorization effect should be selected to improve the taste of oil